HOW TO CHOOSE TENT FABRIC: SILNYLON VS PU NYLON VS POLYESTER

Different materials have unique pros and cons, and choosing the “right” fabric is really a matter of choosing which compromises to make. Do you want it to be lightweight, sturdy, or cheap? You can choose both, but you certainly can’t have all three at the same time.

A common assumption is that by buying an expensive product, you automatically get the “best” product in every way. This may be true for some products, but for tents, there is no “best” choice. It’s like going off-road with a sports car you paid a lot of money for, only to find out it’s not as good as a pickup truck. The same is true for tents. A top tent designed for campers can break in high winds, while a starter tent designed for adventure can easily handle storms. The same is true of fabric selection. Before we design a product, we first assume the environment faced by the user of that product, and then we choose the fabric to make it. The same is true for tent purchasers. Are you going to camp on an exposed ridge, at which point if your tent fails in a storm, you may have to die. We can only assume who the users of our products are before we go about making a tent, so we also want you to be clear about what you want before you buy a tent and then choose a tent made of a specific fabric for your needs.

There’s really nothing complicated about it. The common tent fabrics are nylon, polyester, DCF and even cotton. These fabrics are often used to make tents for different purposes, and they have distinct advantages and disadvantages. Next I will analyze the characteristics of these fabrics.

Nylon and Polyester

Nylon fabric is one of the most common fabrics used in outdoor products, it is very hard-wearing and has a good resistance to tearing. It was used to make parachutes in World War II, which shows that it is very strong and lightweight.

Polyester is a cheap material compared to nylon and we also make some polyester tents, mainly for car camping users who are more sensitive to price than to material performance.

Strength

Nylon is much stronger than polyester. In addition to the strength of the material itself, this comes from the fact that it has a certain amount of elasticity. When nylon is impacted or stretched, the fibres elongate, creating a cushion that keeps the material from breaking, as you might imagine if you couldn’t break a sponge with your fist. But this elasticity can also cause some problems, it can make non-freestanding tents more difficult to pitch and more difficult to produce.

Polyester is a cheap material compared to nylon and we also make some polyester tents, mainly for car camping users who are more sensitive to price than to material performance.

The strength of nylon fabrics can vary greatly from one post-treatment to another. If treated with PU, called PU Nylon, the strength of that nylon will be greatly reduced as the water resistance increases, which is why most manufacturers do not apply a thick PU layer, the thicker the PU layer the more fragile the strength will be and the thinner the PU layer the lower the life expectancy. As you can see, it’s a compromise either way.

The thicker the silicone, the more water and tear resistant it will be, but it will become more slippery and difficult to work with on a normal sewing machine, which means higher costs. Also, nylon that has been treated with double-sided silicone, or SilNylon, cannot be factory taped as PU Nylon tents.

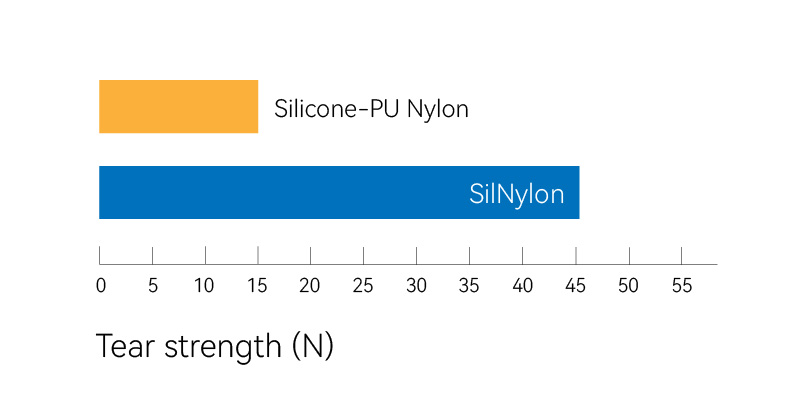

This data is derived from our experiment on one-way tearing of single-ply fabrics with incisions. SilNylon will not be torn apart like paper under the force that exceeds its tearing strength. The slippy fibers will go together and lines up into a strong anti-tear force, and although the tent is damaged at this point, it will not collapse and can continue to provide protection for the user.

Strength : Polyester < PU Nylon < SilNylon

Abrasion Resistance

Nylon is the most abrasion resistant of all fabrics, even better than DCF, which is why it is so widely used in military uniforms.

Abrasion: Polyester < PU Nylon < SilNylon

UV damage

The most significant cause of tent life is UV, which breaks down fabric fibre molecules and subsequently pulverises and breaks them. It is generally believed that nylon is not as resistant to UV as polyester, but according to our tests, polyester is only slightly stronger than nylon, unless the fabric is thickened, no 15D material of the same thickness will last 90 days continuously under strong UV exposure, but this does not mean that the cumulative use is only 90 days, in intermittent use it will last longer, we were also surprised by this result, a possible explanation is The decomposition of the fabric molecules is not linear in relation to the duration of UV exposure, but exponential.

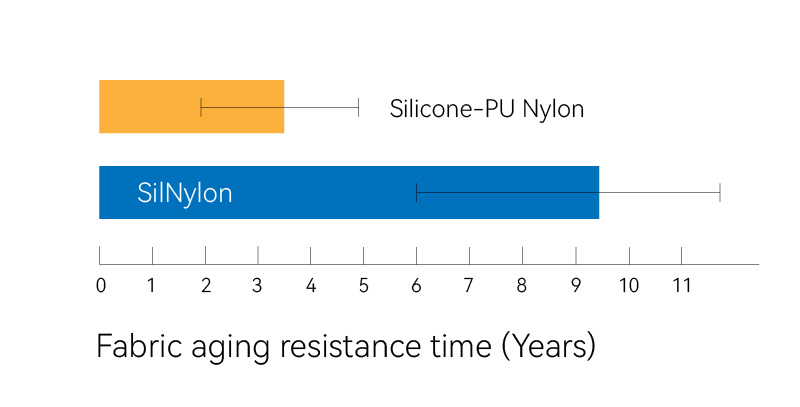

It is worth noting that nylon is far more resistant to ageing than PU coatings, which tend to be the first to decompose under humidity and UV (which happen to be the most common factors in outdoor environments), manifesting themselves in the peeling of the waterproof tent tape and the internal coating becoming sticky, followed by turning white and peeling off. At a waterproofing index of 1500mm, the PU layer is thin and it tends to have a lifespan of only 2 years (under the standard 30-40 days of use per year) or 3-4 years (around 20 days of use per year and stored at a humidity level above 40%).

To eliminate this, there is the option of SilNyon, a method of treating the fabric fibres without a PU coating and only with silicone oil, which will reduce the stretch of the material when soaked in water and increase the life span, but tents made from this fabric cannot be sealed by applying adhesive strips at the factory and have to be bought home to seal the pinholes themselves with silicone.

This is one of the reasons why we use 20DSilNylon rather than 15DPU Nylon in our Lanshan Pro tents. The thicker the fibre, the more resistant it is to ageing. But you will need to seal the tent yourself.

The aging performance of Silicon-PU Nylon in this data is based on our years of repairing tents in the Chinese market, including PU Nylon of brands such as MSR\BigAgnes\3FULGEAR, etc.

Since we haven’t repaired the aging SilNylon tent, the aging performance of SilNylon is based on feedback from our customers and users of backpackinglight.com

Water Absorption

The nylon fabric absorbs water, which can cause problems, the tent can become heavy and the fabric go saggy when it absorbs water, sometimes you have to go out in the rain to adjust the tent to keep the fabric tight. This is particularly the case with PU coated nylons, especially those with a water pressure resistance of no more than 3000mm. This problem is not as serious with nylon coated on both sides with silicon, also known as SilNylon. Because the silicone on both side will prevent nylon from absorbing water.

Polyester fibres have a low water absorption rate and although they do absorb water, they do not experience it as badly as nylon.

Water Absorption: Polyester < SilNylon < PU Nylon

Price

Of the three fabrics themselves, SilNylon is the most expensive, costing US$7-10 per square metre, followed by PU Nylon, which costs US$3-5 per square metre, and polyester, which is the least expensive at just US$2-3. The difficulty of processing also affects the cost. SilNylon is the most difficult fabric to process in the world, being far more difficult than other fabrics, including the expensive DCF. china has the largest textile industry in the world, but few workers are able to work on this fabric. PU nylon and pyrethrum are similarly difficult to process as they are not as elastic and not as slippery.

Polyester fibres have a low water absorption rate and although they do absorb water, they do not experience it as badly as nylon.

Price: Polyester < PU Nylon < SilNylon

Final words

My motivation for writing this article came from a misunderstood experience, once I showed photos of sealing a SilNylon tent, someone told me he was disappointed that 3F UL GEAR tents were not sealed, it was clear that this friend was completely unaware of the properties of the SilNylon fabric and wished he hadn’t bought this type of tent on a whim.

There are no factories in the world that can seal SilNylon tents for now, and if someone suggested that we set up such a factory, my answer would be that it is almost impossible, the tents need at least an hour to apply the glue, 2 hours to dry, and 12-24 hours before they can be packed, which is almost certainly impossible to produce on a large scale, otherwise it would be extremely expensive for warehouse rent.

If you are not prepared to put in the time and effort to get a strong SilNylon tent, or if you simply don’t have the opportunity to use it for hiking in rough conditions, then I suggest go for a tent made of PU Nylon.